Overmolding is a two-shot injection molding process that creates a single part by combining two separate but complimentary thermoplastic materials. The first shot, called …

Search Results for: wall thickness

Part Design: Best Practices For Plastic Injection Molding

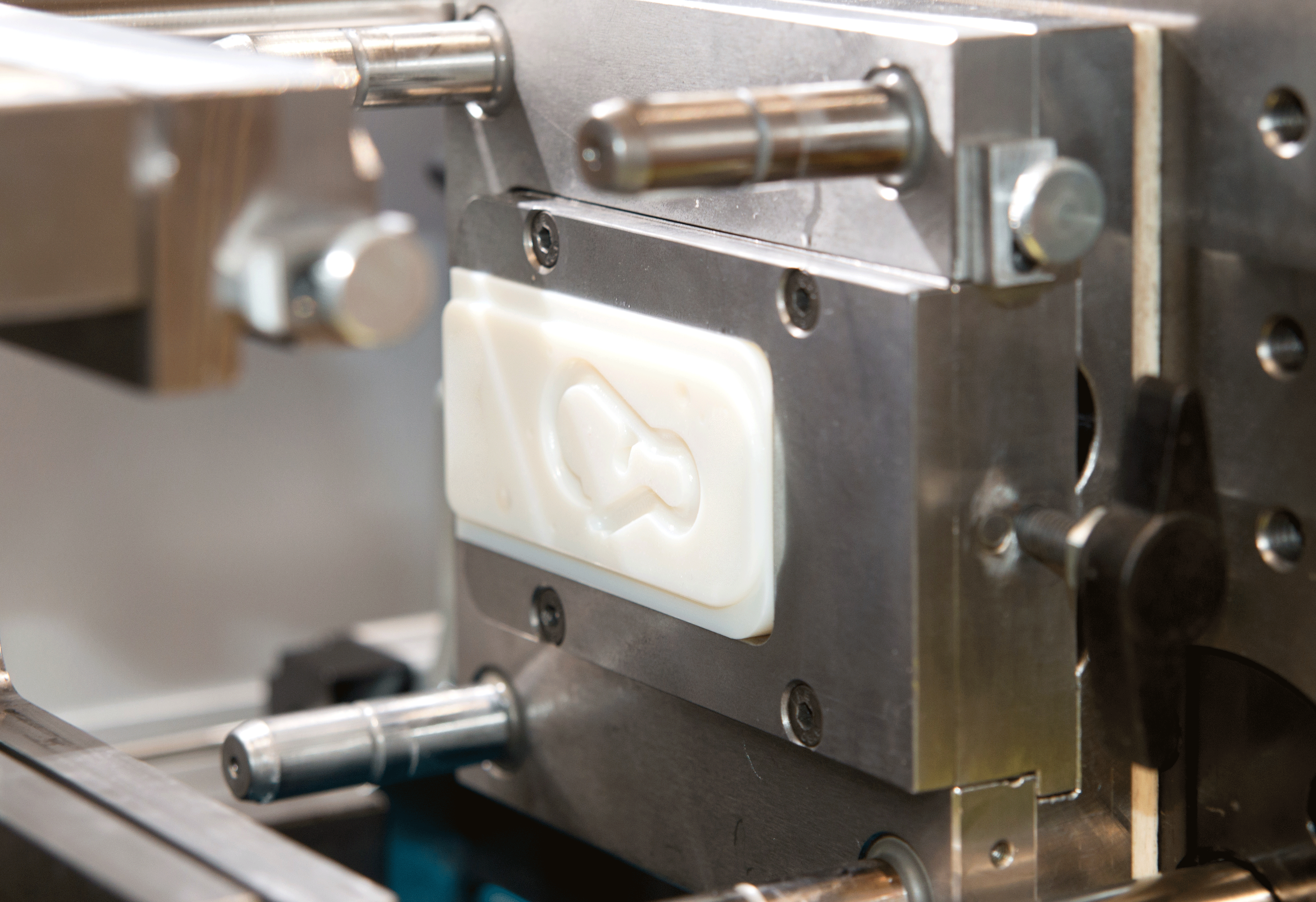

High quality, efficient tooling relies heavily on good part design as well as advanced skills in mold design and the manufacturing of the tool. An injection mold is a highly precision tool that must be rugged enough to withstand hundreds of thousands of high pressure molding cycles.

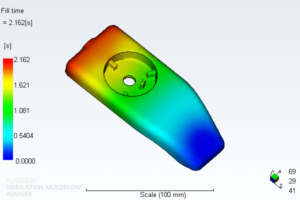

Leveraging Mold Flow Analysis for Injection Molded Parts

When using Injection Molding as a process to manufacture your part, many aspects impact whether or not your injection molded part can actually be produced

Poor steel condition can cause delays.

We find that poor steel condition is a design issue that’s not often thought of in injection molding. Custom part complexities can stress steel that is not rigid enough to hold its form causing breaks.

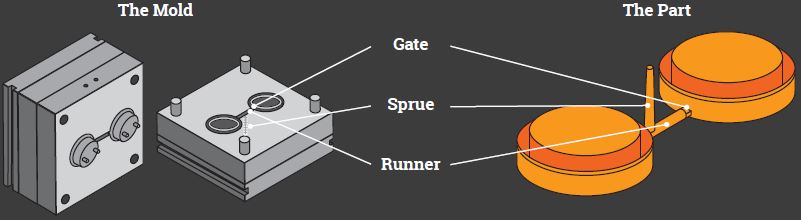

Terminology

Hand Pull Portion of the custom injection mold that is used for creating undercuts in plastic parts. See Fig.1 Slide Portion of custom plastic injection molds

Design Guide for Injection Molding

Our part design guides will help you to address a variety of design challenges. For example, optimizing your part designs for manufacturability, cost, and