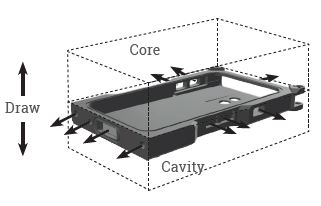

Undercuts Design Guide for Injection Molding An undercut is any indentation or protrusion that prohibits part ejection from a straight-pull mold. It cannot be

Search Results for: undercuts

When And How To Use Undercuts

Learn tips for staying on time and on budget when designing complex parts with undercuts and side action complexities.

How To Use Undercuts In Plastic Injection Molding

Undercuts achieve complex plastic part designs for the injection molding process. For example, overmolding and insert molding.

An undercut is any indentation or protrusion that prohibits part ejection from a mold. It is a feature that the cavity and core cannot capture alone. It is die-locked which prevents the part from being ejected from the cavity.

Undercuts

What is an undercut in injection molding? An undercut in injection molding is any part feature that prohibits an ejection of a part from

Injection Molding First Time Quote

Special Offer for December only! $1,000 off Injection Mold tooling (First-time customers only) Injection Molded Parts in as few as 5 business days. Submit

Injection Molding: Typical Plastic Resins used in Injection Molding

Typical Plastic Resins used in Injection Molding Injection molding is used to make plastic products, but what is its purpose? Plastic industries need