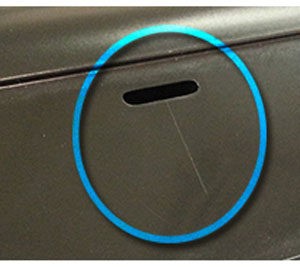

Knit lines are formed when two or more plastic flow fronts collide and solidify or “knit” together during the molding process. Overall, injection molding

Search Results for: knit lines

Knit Lines

As the plastic travels through the cavity it wants to naturally cool. This is because the melt temperature is much higher than the mold

Designing The Best Living Hinge

Innovation in digital manufacturing means designing products with enhanced functionalities, made cheaper and delivered faster. But innovation can also be translated right down to

6 Common Plastic Resins for Injection Molding

Material selection is critical for designing and developing robust and long-lasting products. However, with over hundreds of plastic resins on the market to choose

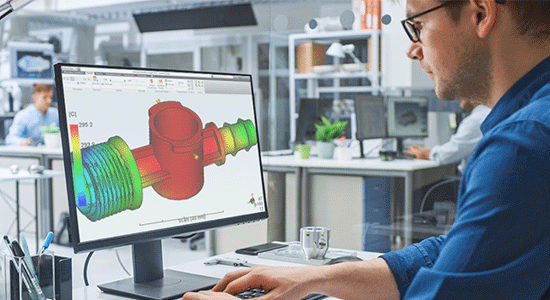

Mold Flow Analysis For Injection Molding

Designing Plastic Parts For Injection Molding? Run Mold Flow Analysis Before Cutting The Mold Mold flow analysis is not required for the injection molding

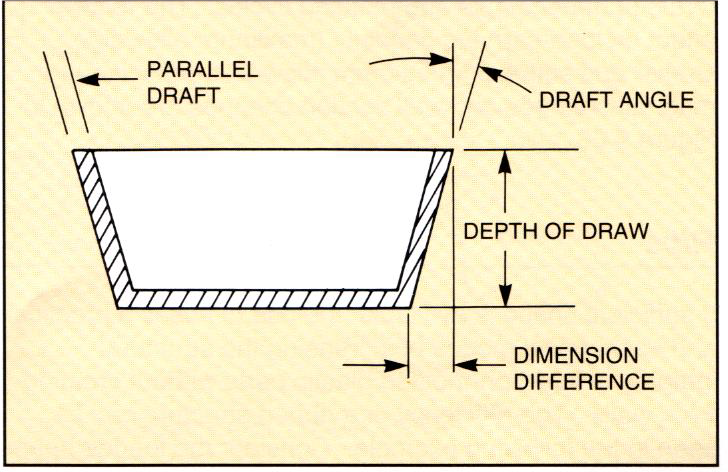

Designing for Plastics

The success of your plastic part relies upon many key elements working simultaneously. There are many factors that influence the outcome of your plastic part and should be taken into consideration when designing with plastics as follows: