Computer numerical control (CNC) machining is a manufacturing process where material is removed from a block of raw material—the workpiece— with a computer-controlled rotating cutting tool until the desired machined part is formed.

CNC machining is one of our core digital manufacturing services here at Xcentric Mold & Engineering. Using only the latest automation technology, CNC is ideal for our customers’ high precision machined parts. It is also generally the cheaper option (compared to additive manufacturing) as production ramps up and can be used on a variety of materials.

As a fully automated subtractive manufacturing process, CNC machining delivers:

✓ Very precise, high-quality machined parts

✓ Reduced overall production time

✓ Design changes that can be made throughout

Let’s look closer at how CNC machining works, including what CNC programming is and how to use a CNC machine.

How CNC Machining Works

CNC machining is commonly used to produce machined parts from a full range of metals and plastics. At Xcentric, this includes:

- Aluminum

- Brass

- Titanium

- Stainless steel

- Common steel

- ABS

- Acetal

- HDPE & LDPE

- PEEK

- PVC

Thanks to its versatility, CNC machining can also be used on workpieces made from wood, glass, ceramic, and foam.

CNC Programming

Geometry code, or G-Code, is the programming language of the CNC machine.

The control computer on a CNC machine reads the G-Code file line by line and then commands the rotating cutting tool to carry out the movements—a major upgrade from traditional milling machines that were manual and required an operator to control the movements by hand.

There are three ways to program a CNC machine:

- For very simple operations, the G-Code program can be entered manually through the MDI (manual data input) of the control computer.

- For more complex designs, a 2D or 3D model can be imported with CAM (computer-aided manufacturing) software to generate a G-code file that is then loaded into the CNC controller.

- Complex designs can also be imported as a 3D model of the machined part on CAD (computer-aided design) software. CAM software is used to specify the cutting operations to generate a G-code file which is then loaded into the CNC controller.

These front-end automation capabilities are what makes CNC machining fast and precise, allowing a high-quality part to be machined in less than a day.

Types of CNC Machines

A CNC machine is made up of:

- The machine base

- The computerized controller

- The spindle which rotates the cutter or part

- Rotating cutting tools

The most common CNC machines used in digital manufacturing are mills and lathes.

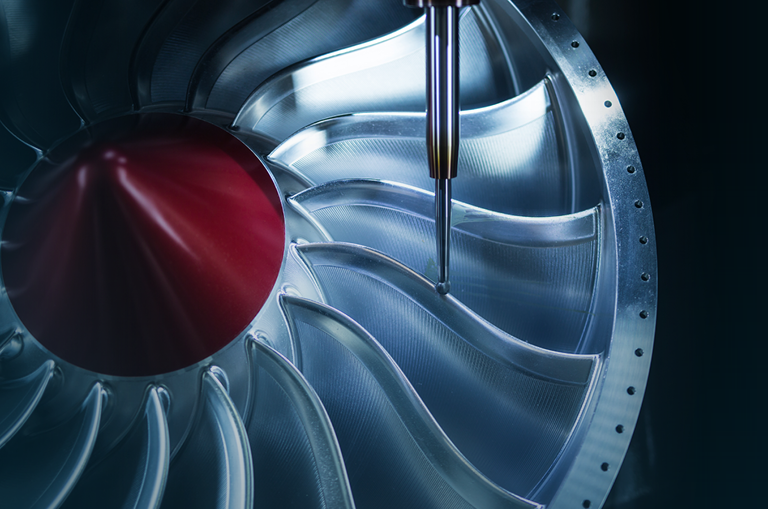

CNC Mills

CNC mills keep the workpiece stationary while the spindle and cutting tool move.

Common applications for CNC milling include jigs and fixtures.

CNC milling machines vary in their ability to work on complex designs—CNC axis machining plays a key part in the process. CNC axis machines range from 3-axis milling machines that perform simple operations to 5-axis milling machines for more sophisticated operations.

- 3-axis machining, where the three linear axes move simultaneously – X (side-to-side), Y (front-to-back), and Z (down-and-up).

- 3+1 axis machining, where the linear movement can combine with one rotational axis (but not simultaneously).

- 3+2 axis machining, where the linear movement can combine with two rotational axes (but not simultaneously).

- 4-axis machining, where rotation on one axis occurs simultaneously to the linear movement.

- 5-axis machining, where rotation on two separate axes occur simultaneously to the linear movement.

CNC Lathes

CNC lathes or turning machines rotate the workpiece while the cutting tool moves in various axes.

This makes CNC turning ideal for complex cylindrical shapes like shafts, pipes, pins, and pulleys.

A mill turn or live tooling is a special type of lathe for creating round parts with milled or drilled features on them.

Other Types of CNC Machines

These CNC machines are also used in digital manufacturing, but they differ from mills and lathes as they do not have spindles:

- CNC plasma cutters for cutting through sheets and plates

- CNC electric discharge machines (EDM) use electrical discharge to erode a workpiece in a process also known as spark machining

- CNC water jet cutters that can cut through stone and granite

- CNC laser machines that can cut through acrylic and polymers

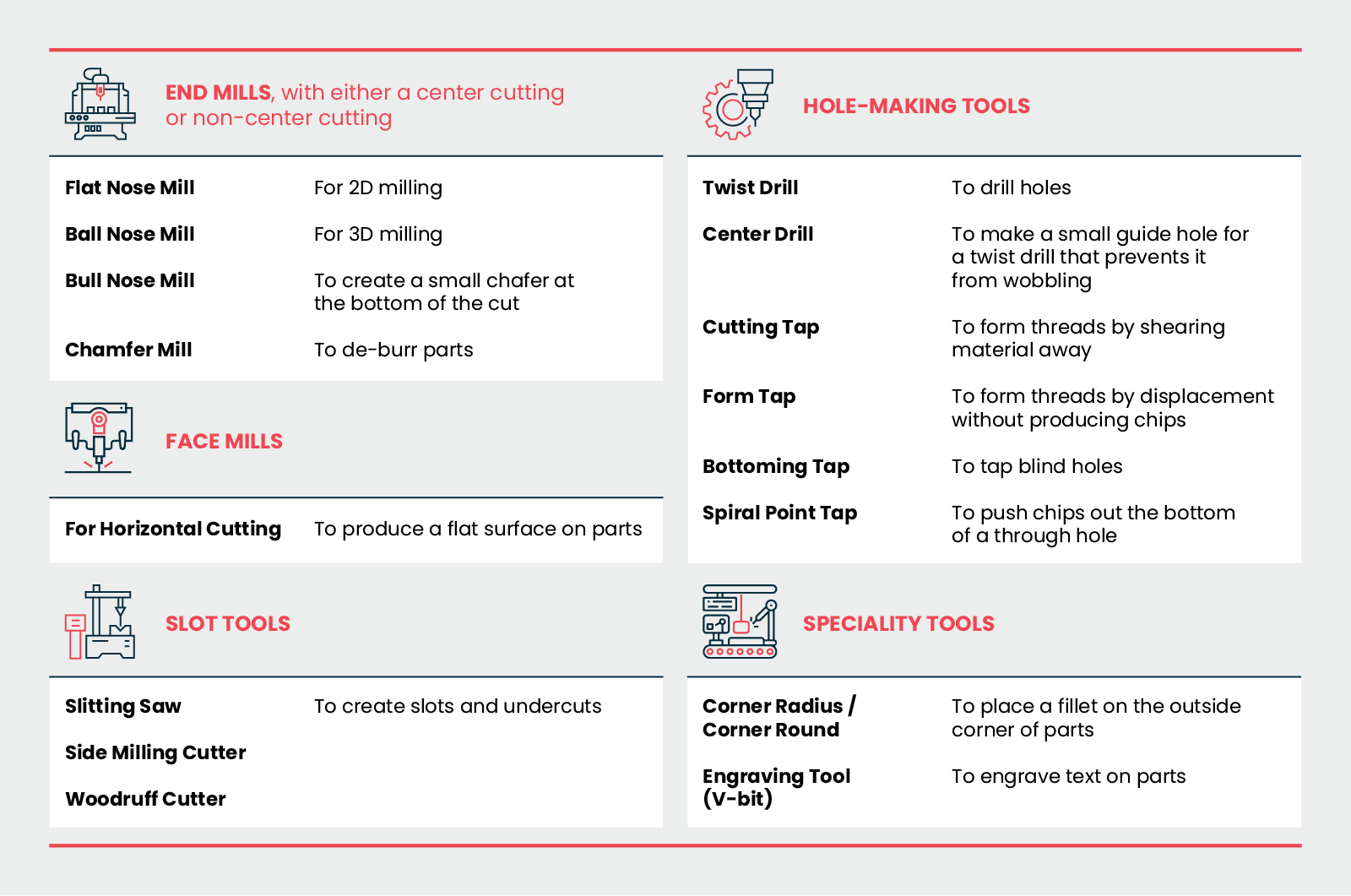

CNC Cutting Tools

CNC Finishes and Coatings

Once the machined part is formed, it can also undergo secondary surface treatment such as:

- 320 paper to remove cutter marks left behind from the CNC machining process

- 400 paper as a smoother alternative to 320 paper

- 600 paper for a smooth finish

- 1500 paper for an optical smooth finish

- Light bead blast for a smooth, uniform sheen

- Heavy bead blast for a light, textured appearance

- Anodizing for a protective and aesthetic coating

- Powder coat for a more durable, corrosion-resistant layer

- Chrome plating for a mirror-like finish

Strengths and Limitations of CNC Machining

As with any digital manufacturing procedure, CNC machining comes with its own set of strengths and limitations. When talking to our customers who are considering CNC machining services over 3D printing or injection molding, we discuss a number of key factors with them.

CNC machining can be used at any stage of the product development lifecycle, but it does require some post-processing. It can handle both simple and complex designs. Complex designs will cost more. CNC machining can also be expensive (cost per part) for smaller production runs as a good portion of your costs are made up of set-up charges and programming fees. If full automation is required, you will need a highly trained operator with strong programming knowledge, which adds to overall costs. However, as you work toward larger production runs, this cost levels out and CNC machining becomes a very cost-effective solution. CNC machining works well on a wide variety of materials, but keep in mind that there is often heavy material waste.

So how do you know whether CNC machining is right for you? Engaging an experienced rapid manufacturing partner like Xcentric—with strong CNC machining experience and an engineer-centric approach—will help you make the right decision for your projects. If you have a quick turn project you need help with, submit your project here and our team will be happy to provide expert advice. Whether your parts are simple or complex, we can handle most projects in 15 days or less.

About Xcentric

Founded in 1996, Xcentric Mold & Engineering is an innovator of on-demand digital manufacturing and continues to lead advances in injection molding and rapid prototyping. We know what it takes to deliver a high-quality product on time and on budget. Xcentric is engineered to be nimble, employs a team of experts in injection molding, and takes anengineer-centric approach to everything we do. Tens of thousands of product developers and engineers across North America trust Xcentric to bring their products to life.

Learn more about what Xcentric can do for you here.

Questions? Contact our friendly sales team here or on 586-598-4636.