We back this up by guaranteeing that if a client wishes to produce additional parts in the future we will produce the parts on-demand as needed for up to two years for a nominal set-up fee and per part charge. In fact, as long as the customer continues to reorder from Xcentric molded parts from that mold at least once per year, we will store and maintain that mold indefinitely. Alternatively for a nominal annual storage fee we will keep the customer’s mold at the ready to assure we can react as quickly as possible to requests for additional components. Specific terms and conditions apply so please ask your salesperson for details.

How are we able to offer this guarantee?

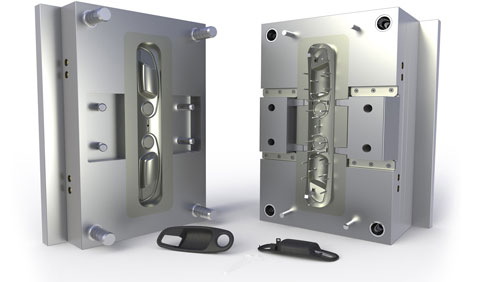

Xcentric was founded by experienced second generation mold makers who fully understood the importance of building tools to last, even if the core focus was on prototype and short run production. High quality molds will yield better molded products from the first shot to the last, are easier to maintain, and are ultimately less costly for the customer than lower cost molds that are unreliable or require frequent repair.

Staying true to this core philosophy, Xcentric developed its internal mold production process to maximize the quality of every mold whether it is for ten parts in a forgiving resin or hundreds of thousands of parts in a more challenging filled polymer. Our careful attention to quality at each step of the design process, CNC machining process, polishing and texturing process, mold assembly, molding, and ultimately mold storage and maintenance plays an important role in assuring our molds are in top condition for our customer’s processing.

Start Your QuoteA few factors to consider about our molds

- Xcentric only uses quality mold components and mold materials, specified for their combination of ease of manufacture and long term wear resistance

- Our injection molds are designed and CNC machined to high tolerance tool metal conditions reducing the metal to metal shock during the molding process. This increases the life of the tool and reduces the need for tool repairs even after tens of thousands of parts have been molded.

- We use our Proprietary Process Engine to process every part. This reduces the likelihood of over–shooting the part or applying too much pressure to sensitive mold features

- Xcentric has its own tooling room where each mold is maintained every time it is run

- We run parts on all electric injection molding machines. These machines are equipped with mold protect sensors that reduce the likelihood of over–clamping or smashing of parts in the mold

- We personally stand behind every mold we build and run.

Experts in Design

Xcentric has served the quick-turn, plastic injection molding industry. With the advancement of in-house technologies, we now offer CNC Machining, Rapid Prototyping and 3D Printing Services in addition to our core injection molding service.

Start Your Quote