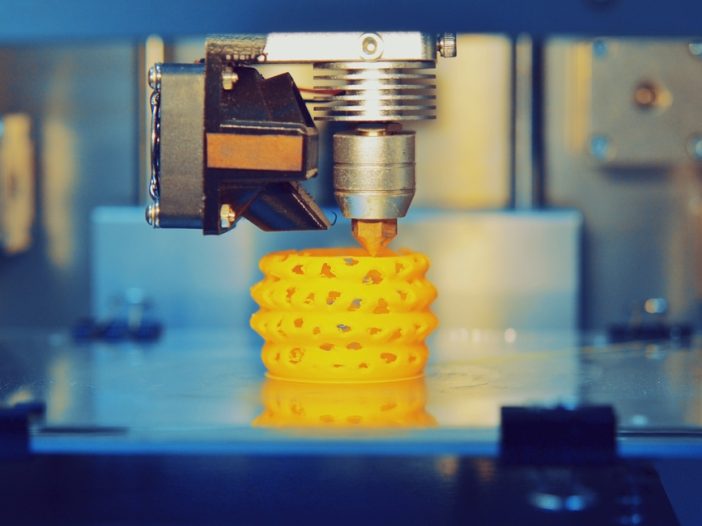

3D Printing is important in most workplaces. It allows companies to bring products to the market, perform functional tests, and validate their designs. Prototypes of 3D prints are good for communicating concepts to stakeholders. This technology has resulted in good quality products and faster iterations. Outsourcing also becomes integral for 3D printing. In this article, we will analyze both the pros and cons of 3D printing.

In-house or Outsource 3D Printing

Below, we will list the pros and cons of in-house and outsourced 3D printing.

Pros of In-house 3D printing

1. Compared to outsourcing, in-house 3D printing can be more cost-effective. This is because associated costs such as delivery and shipping are eliminated.

2. If you need fast iterations and quick turnarounds, having an additive manufacturing system will be worth your investment. Once the training and systems are in place, you can meet project deadlines more easily with the help of on-demand production.

There can also be tweaks in the design without the costs of shipping associated with the outsourcing. With in-house 3D printing, you can save time by overnight printing or printing over the weekend.

Cons of In-house 3D printing

1. There will be a significant upfront investment. You may have to pay around one million for a good manufacturing system.

2. They are not suitable for short batches. They cost more for each product.

3. It requires a lot of space. True manufacturing systems only need 30 m2 of cleaning stations, floor space, finishing stations, and industrial HVAC.

4. A single build will be more expensive than a 3D desktop printer. This can be three thousand dollars plus the labor and the usage.

Pros of Outsourcing in 3D Printing

1. As the service bureaus will be the owner of several technologies, outsourcing will provide companies with a major selection of 3D printing materials and technologies. This will mean that the organization can check out different options without requiring to invest in several systems.

2. If you outsource the AM production, you will not need to invest in expensive AM systems. Service bureaus will offer a vast range of technologies and machines. You will even be able to save the costs of any ongoing maintenance.

3. Service bureaus, in general, possess a high degree of expertise and are in a position to advise you regarding the most suitable considerations of designs along with materials. Some bureaus also provide finishing and design services, both of which significantly require post-processing and data preparation.

Cons of Outsourcing in 3D Printing

- It is not scalable.

- It will take longer to create multiple iterations.

- The cost for each part is higher than the cost of in-house printing.

- It is a slower process that can take weeks instead of days.

- There will be structural underutilization.

- An operator will be required. Engineers cannot use it directly. Maintenance will denote non-availability.

- Small amendments will be expensive.

Factors to consider while choosing between In-house and Outsource 3D Printing

1. The use

Your use of the technologies and, accordingly, the intricacy and functionality of your portion are two of the most vital factors to consider.

For instance, choosing an internal AM system—of which numerous desktop systems are available on the market—will be more cost-effective in case you have the requirement to generate scaled models or functioning prototypes that will be utilizing various design iterations.

For specialized end parts, outsourcing might appear to be a more reasonable strategy. Service bureaus are knowledgeable about requirements as per the design for manufacturing processes, for instance, because they have a proper team of experts and engineers. They also have a larger choice of equipment with more printing capacity.

2. Flexibility of design

One of the main advantages of 3D printing is its flexibility in terms of design. You want to design a part, evaluate it, and make any necessary adjustments, but then just print it again when a product remains in the testing stages. This is greatly simplified and quick when using in-house 3D printing because you can rapidly apply necessary modifications there.

Changes often take longer to adjust when additive manufacturing is exported since parts must be delivered and printers must be operable, among other factors.

Small series production will not have a problem if the design is fixed at this stage. In-house 3D printing is best for speedy design iterations.

3. Location

The location where you will require your products must play a significant role in your decision-making. In case you only require to produce the parts within a region or a country, having central printers will be your best option.

However, if you want parts globally, shipping the parts to the other end of the world will be quite expensive. In addition, there will be disruptions in the current chain of supply that can result in a delay in delivering the parts at the appointed time.

Thus, your solution will be engaged with multiple 3D firms with a global print network. If you have a 3D printing platform, it will give you access to production all over the world.

4. Investment

There are budget-friendly desktop printers that are available all over the market. However, for technologies like the SLA or FDM, you may require high-end AM systems that need upfront investments.

Apart from the printers, employee training, maintenance, and material procurement will contribute to the overall cost.

You may also need new employees who can use your 3D printers along with a larger space. This will increase the costs.

Thus, we can say in-house 3D printing requires a massive investment.

Final Words

In-house or outsourced 3d printing? If you want to save money, you can use in-house 3D printing. In terms of outsourcing 3D printing, you will get access to a lot of machines. The cost will be higher. Xcentricmold will enable you to reach out to a team of experts who work with precision and cutting-edge technology that simplify the design to the prototype processes.