Leveraging Mold Flow Analysis for Injection Molded Parts

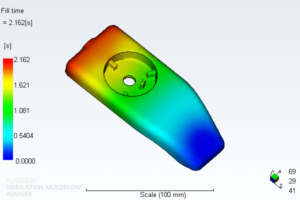

When using Injection Molding as a process to manufacture your part, many aspects impact whether or not your injection molded part can actually be produced

Continue Reading

When using Injection Molding as a process to manufacture your part, many aspects impact whether or not your injection molded part can actually be produced

Continue Reading

Draft angles allow for the removal of plastic from an injection mold. Applying the proper draft angles (or tapers) on the surface of an injection molded part is critical to part moldability.

Continue ReadingWe find that poor steel condition is a design issue that’s not often thought of in injection molding. Custom part complexities can stress steel that is not rigid enough to hold its form causing breaks.

Continue Reading

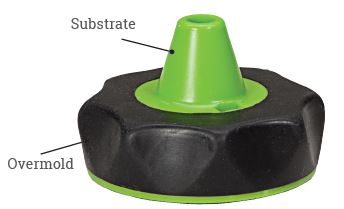

One of the more common reasons to utilize the overmolding process is to create a soft grip. Pulling from the example used below, the green part …

Continue Reading

We’ve seen a need out there for the product developers to help get their parts to market quickly…where our specialty is helping the customer get …

Continue ReadingTolerances play a crucial role in determining the performance of your end product. Selecting the proper tolerances can assist in ensuring product quality, ease of manufacturing and faster time to market. Click here for some tips on factors that impact tolerances.

Continue Reading