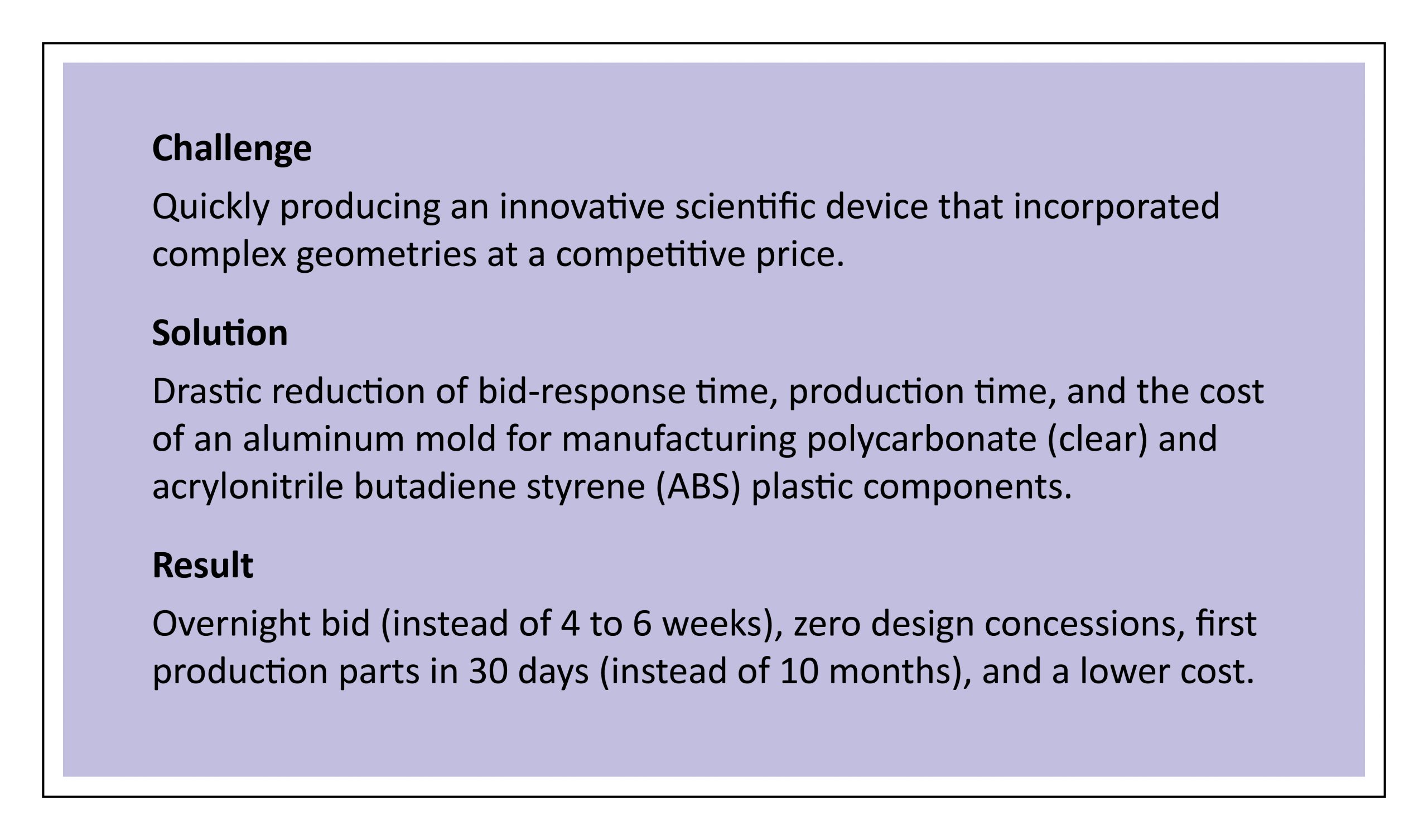

Celling Biosciences Receives Complex Parts in 30 Days

Medical and scientific devices pose three key challenges for companies like Celling Biosciences: time, quality, and cost. On one hand, to build a reputation for …

Continue Reading

Medical and scientific devices pose three key challenges for companies like Celling Biosciences: time, quality, and cost. On one hand, to build a reputation for …

Continue Reading

There are many elements that influence the plastic injection molding manufacturing process. A key component to this process is the material used to create the part itself. There are numerous thermoplastic resin material options that are available for plastic injection molded parts. The content of these materials will directly affect part production. It will impact several critical factors in the manufacturing process such as strength, durability, cost of production and time to market.

Continue Reading

Great Surface Finish – But How Will It Look On Your Plastic Part? Request a FREE Surface Finish Sample Kit. Design for injection molding

Continue Reading

Complex insert molding is sometimes utilized in order to get parts to market faster. It is a process in which plastic is injected into a mold that contains a pre-placed insert. The result of insert molding is a single molded plastic piece with an insert surrounded by the plastic.

Continue Reading

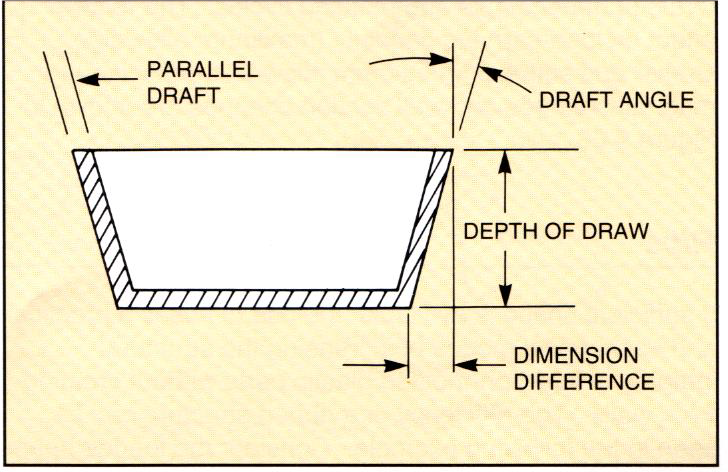

The success of your plastic part relies upon many key elements working simultaneously. There are many factors that influence the outcome of your plastic part and should be taken into consideration when designing with plastics as follows:

Continue Reading

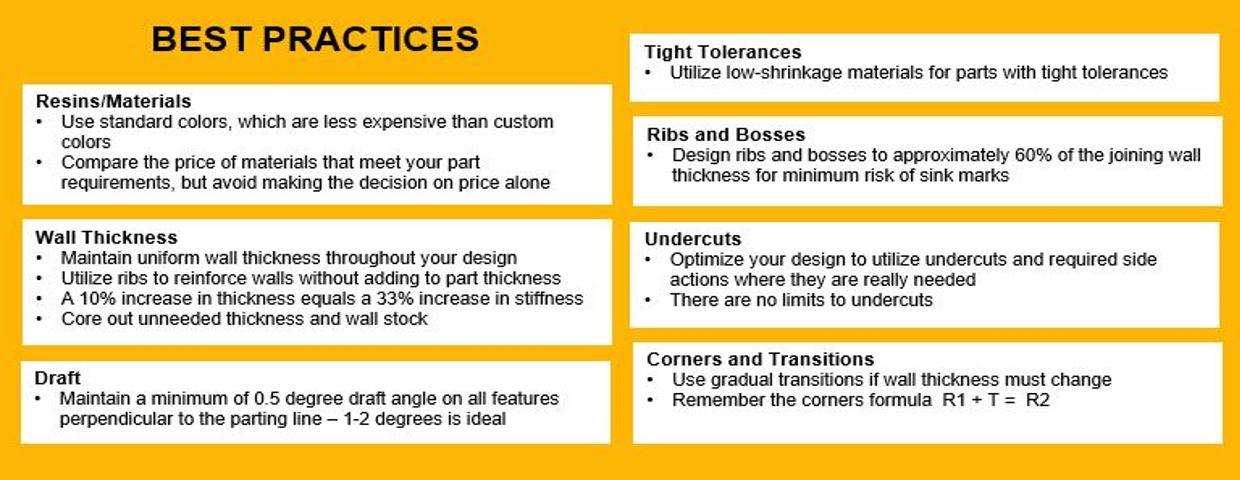

Designing your part for the plastic injection molding process can sometimes be a challenge. Refer to our quick reference guide below featuring some best practices …

Continue Reading