About Insert Molding

There are many substrates used in insert molding, but the most popular is brass threaded inserts and bushing. In addition, many companies make custom inserts that can be insert molded. It is really left up to the imagination when deciding what type of inserts can be over molded.

The benefit to insert molding is that parts can be mass produced faster than machining whole parts out of metal. Even though insert molding adds to the cycle time (typically 15 seconds per insert) it is still much faster than cnc machining a part from a solid block. Furthermore, by insert molding metals where necessary and replacing the rest of the part with plastic will in turn reduce the overall weight of the part.

Did you know you can insert mold plastic parts? This process is called over molding and it lends itself when you need two or more different materials in the same part.

Furthermore, Xcentric Mold & Engineering is one of the few injection molding companies that offer over molding and insert molding services.

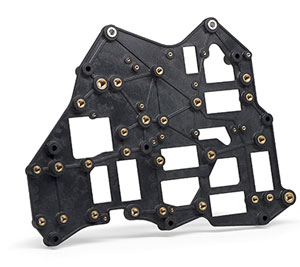

Custom Insert Overmolding.

The part below was created using a custom metal insert supplied by our customer. Because of our skilled mold design engineers we were able to mechanically place the insert into the mold and inject the plastic around it.

Let us quote your next project. We are sure to take the headache out of your next Insert or overmolding project, as we know these projects can be very complicated. In addition, we have Insert and overmolded parts with over 37 inserts in one part. At Xcentric, there is not an Insert or overmolding project we will not tackle.

Need More Support?

At Xcentric our aim is to give the design engineer all the tools needed to make a fast educated decision. That is why we have assigned a technical team to all of our accounts. Furthermore, we believe that the fastest way to market is by preventing issues early on in the process. Here are some key points that set us apart from other companies.

- Online quote system – Our Online quote system gives our customers instant access to a technical team. Your team is made up of a tool engineer and a sales rep. Once a quote is submitted online, you will have a response within 24 hours. In addition to that, your quote will be managed through our customer portal.

- Customer Portal – Our online customer portal gives you 24-7 access to Xcentric from anywhere in the world. In the portal you can;

- Submit quotes

- View and interact with a live interactive quote. This allows you to change features and the price is updated instantly.

- Purchase Tooling and Parts.

- Instantly Re-order parts.

- View history details such as invoices and Purchase Orders

- Initiate Engineer Changes

- Organize Parts by type.

- Update and manage Account Information

- And many more. We are always adding features to support our customers needs

- ISO, ITAR and UL Certified

- Dedicated Support Team

- Custom Material Selection – We run more custom resins than any other injection molding company.

- Free Part Design Analysis – You assigned technical team will review your part and make sure it is ready for the manufacturing process.

- Budget – Let our sales team find the right process for your budget.

Insert Molding Services Provided

- Brass Bushings

- Threaded Inserts

- Magnets Overmolded

- Bushings

- Custom Inserts

- Plastic over Plastic Substrate

- Plastic Over Custom Inserts of any Material

- Chemical Bond Overmolding

- Plastic over Threaded Inserts

- Mechanical Bond Overmolding

- Medical Instrument Overmolding

- Electronic Overmolding

- Wire Overmolding