Developing & producing injection-molded products follows a proven process

The process for launching a product that includes injection molded components has been continuously developed for decades, and most commonly includes the distinct phases seen in the graphic below. Each phase builds on the last, generating additional information necessary to bring a high-quality product to market in commercially relevant volumes and at an acceptable cost. Prototype tooling plays an important role in this process.

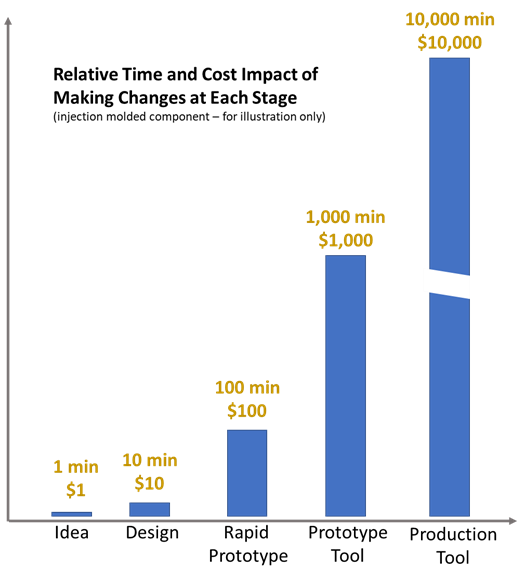

The time, energy, and expense associated with each phase is of course highly dependent on the design and functional parameters of the desired product, but for the sake of our discussion, we can employ the oft-used rule of thumb that the time and cost of making changes to a product is roughly 10X that of the previous step. While this is clearly a gross oversimplification for any complex product, it does serve to illustrate a few key points that are relevant to product designers, project managers, and business unit executives:

1) More information earlier in the project reduces risk

2) Earlier identification of design and manufacturability problems reduces overall project cost

3) Changes are much less expensive earlier in the process

Skipping steps must save time and money, no?

It may seem logical to think that skipping steps in the process would reduce the time and cost of bringing a product to market. Certainly there are examples of this, perhaps a simple bottle cap that has only minor changes in lettering or texture from previous versions, where the molder has sufficient experience to go directly from CAD design to production tooling.

It may seem logical to think that skipping steps in the process would reduce the time and cost of bringing a product to market. Certainly there are examples of this, perhaps a simple bottle cap that has only minor changes in lettering or texture from previous versions, where the molder has sufficient experience to go directly from CAD design to production tooling.

However, for most complex designs, say for an ergonomic consumer product with unique features, past experience, simulation, and rapid prototyping might not provide sufficiently accurate predictions of how the product will appear, what critical dimensions will be held, or how it will function when molded in the production material.

Rectifying problems in production tooling is difficult, expensive, and time consuming

Once a design for a high productivity steel injection mold has been completed and mold production starts, the costs to make changes becomes much more expensive simply due to the time and effort it takes to make even minor, much less major, changes to the tool. Additional CNC, EDM, benching, and texturing time add up quickly. The very nature of hardened tool steel, especially if it has been highly polished or textured, makes it difficult to modify. Compounding this is the time it takes to remove the tool from the press, return to the mold making department (if in house) or transport to an external mold maker for modification. All of this can easily add up to weeks of delay even with minor modifications, especially if the production tool has been sent to another country for molding operations.

How does investing in prototype tooling save money?

Firstly, let’s define prototype tooling, since it means different things to different people. In the case of Xcentric, it means high quality injection molds produced with state-of-the-art CNC equipment and finished by master mold makers. The mold material is a premium grade of aluminum developed specifically for injection mold applications. You can read more about the Xcentric mold making process here.

Xcentric prototype injection molds help our clients save money in the following ways

- Reduce the cost of making corrections to injection molded components during validation and pre-production

- Reduce the cost of exploring design and material options

As noted above, the costs of making changes to a production tool are many multiples of making changes to prototype tooling. In the case of a multi-cavity production tool, the costs are similarly multiplied should a change be required in the design of the tool or part. Secondly, if there are still open questions about the design of the component including material choice, the cost of doing this experimentation in hardened steel is typically prohibitive.

Validating or correcting early in the process is extremely valuable

In the case of Xcentric, we typically turn around injection molded projects in under 13 business days, and upon request for certain products in under five business days. Even if done sequentially, this is time well spent because this activity is completed so early in the project. Problems can be identified and corrected weeks or months before the same issues would have been uncovered in production tooling. While it is fully understood that there is not a 1:1 correlation between the performance of some aspects of prototype tooling versus production tooling, particularly related to high cavitation fill balancing, feedback on dimensional issues, material behavior, shrinkage, warp, sink, splay, and aesthetics can all be gathered in the desired production material in an Xcentric prototype mold.

The graphic below illustrates the standard process versus a process imagined to save time by skipping prototype molding. Important points to note are: the time to a) recognize and b) correct for problems is weeks earlier, and depending on the severity of the change required, the overall project time can be shorter even including making changes to the prototype tooling.

Reducing product launch risk is even more valuable

By identifying and addressing production issues early in the process, project managers help to de-risk the overall project by giving themselves enough time to react. Executive management and down-stream customers do not typically respond well to learning just before the originally scheduled product launch that there are delays due to production tooling that may push back launch by several weeks. It is generally accepted that significant delays in new product introductions in many industries have a huge deleterious effect on the total net present value of the product launch. Inevitably the questions come like “Why wasn’t this caught earlier?” One difficult to explain answer is “Budget for prototype tooling was eliminated.” (that would have been a small fraction of the cost of the production tool changes and product introduction delay). In this light it is fair to say that prototype tooling is a valuable insurance policy to help reduce the risks associated with new product introductions.

Key takeaways about the money and time saved by prototype tooling

Including the process step to validate designs, identify improvements, and avoid downstream problems using prototype injection molding has been proven on innumerable projects to save both time and money. Learning and correcting early in the process pays dividends for project risk mitigation. Ultimately it is all about bringing the best possible product to market as quickly as possible, which happens to be Xcentric’s mission.