One of the most fundamental questions asked in product performance is: Are we using the most optimal material for this application?

Whether it’s high-performance plastics or metals, gains are made when the right material is used in a product or part. A race car can save a few kilos in weight—and win! A coffee brewer product that was initially a no-go can become commercially viable. An inhaler’s sterilization capability can improve so much that hospitals adopt it quickly.

In the numerous injection molding projects Xcentric has delivered for its clients, we know there are applications where high-performance plastics are not viable substitutes for metal alloys. But in many other applications, we have found that polymers do outperform metals.

Take Delrin plastic, for instance. Also known as PolyOxyMethylene (POM), Delrin is a brand name for Dupont’s acetal polymer. It has two distinguishing factors when compared to other acetal plastics:

- A uniform semi-crystalline molecular orientation: This means it is stiffer than other acetal plastics and therefore has more mechanical strength.

- A porous center: During the cooling process, gas escapes from the center of the plastic. While this is not an issue for most industrial applications, the risk of bacterial growth at the centerline can be risky for certain food and medical applications.

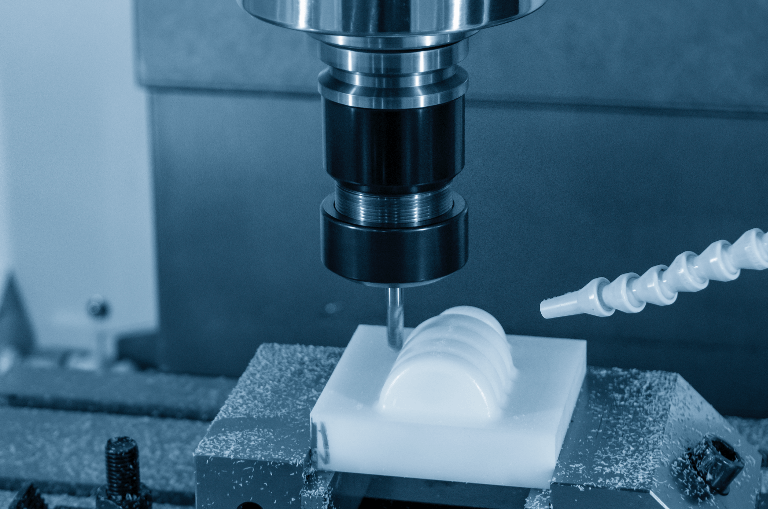

Delrin plastic is often used in CNC Machining, Injection Molding, and 3D Printing because it is durable and robust. It is hard—which helps when you’re working on a part that needs to be precise and accurate. It resists high temperatures. It is also wear-resistant, which makes it suitable for additive manufacturing. There are many more properties to Delrin and its different grades.

Read on to understand why you should consider Delrin plastic for your projects.

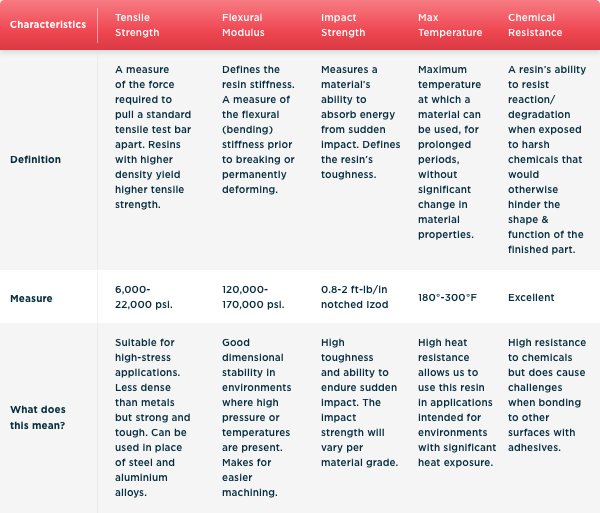

Delrin Plastic Properties

The properties of Delrin plastic can be measured across a range of characteristics. We further define what it means for material selection in your projects.

Delrin Plastic as a Metal Alternative

There is a strong case for Delrin plastic as the ideal solution for your parts and projects. In some cases, the reward is obvious. Like in the race car example mentioned earlier. But in other cases, the math becomes more complex. We help you weigh up Delrin plastic as an alternative in your material selection.

Delrin Plastic vs Metals

To decide between plastics and metals, the benefit to cost ratio is important. So how do you start evaluating?

- Evaluate a simple material substitution of the component design

Say you’ve prototyped a part using a metal alloy. Try using an engineering-grade polymer with essentially the same physical and geometrical design as the initial metal part. Despite the differing mechanical properties of metals and polymers, you might achieve meaningful improvement if the initial metal design was far from optimal. The lighter and less expensive-to-manufacture plastic component then becomes your best option. - Evaluate a redesign that takes into account the advantages of molded plastics

Molded polymers can incorporate aesthetics via more complex shapes and molded-in colors. A designer can reduce the number of parts in an assembly by combining functions into a single component. This reduces secondary operations, saving time and costs. - Evaluate combining the best of both worlds

When polymer components require overmolded inserts, a designer can leverage the combined benefits of polymers and metal features in certain critical areas: threads, embedded wiring, metal tubing for fluid or gas lines, heat dissipation features, and aesthetic elements.

Pros and Cons of Delrin Plastic

The advantages of Delrin plastic include:

- High tensile strength with rigidity and toughness

- Good shock impact and stress resistance

- Good chemical resistance

- Glossy molded surface

- Low static and dynamic coefficients of friction (low friction during machining)

- Many grades have FDA and NSF approvals on food and water contact

- Replace die-cast metal components

The disadvantages of Delrin plastic include:

- Difficulty in bonding

- Poor resistance to acid and bases

- Subject to UV degradation—outgassing problems at elevated temperatures

- Brittle at lower temperatures

How to Choose the Right Delrin Material

Delrin plastic is available in many grades—100, 500, 900, and 1700. The grades refer to their melt viscosity, with 100 the most viscous and 1700 the most fluid. Choosing the correct grade depends on your fill requirements and end-use function.

At Xcentric, we offer the most popular grades of Delrin to help our customers choose the best application for their part or product. These include the Delrin 150 Homopolymer in Natural and Black, and Delrin 570 (20% Glass Filled) in Natural.

Overall, Delrin plastic offers strength, toughness, dimensional stability, and natural lubrication for good machining capabilities. But what makes a particular grade stand out?

Delrin Plastic in Rapid Prototyping

Rapid prototyping involves the fast creation of parts. A material like Delrin plastic that is stable and has a high machinability rating makes it very suitable for rapid prototyping.

In CNC machining, the material used needs to be hard and highly tolerant. Delrin plastic does the job.

In Injection Molding, the material needs to melt and be molded into the right shape. Delrin plastic is an ideal choice.

In 3D Printing, a prototype is created layer by layer and therefore the material used needs to be wear-resistant. Delrin plastic filaments make a great selection.

Application of Delrin in Rapid Prototyping

Delrin plastic is used widely in various industries and in many prototyped applications. Here are some examples:

Automotive: Slides, Gears, Cams, Bushings, Door Handles, Seat Belt Parts, fuel system components, loudspeaker grilles

Industrial: Conveyor chains and links, farm machinery, irrigation sprinkler components, gas and water meter components

Electrical: Switches, buttons and knobs, laser printer gear trains, audio, and videotape cartridge platforms

Household Appliances: Hand mixers and bread slicer motors, garage door opener, knife handles, soap dispensers

Consumer Products: Zip fasteners, clips, fasteners, buckles, pen components, gears in toys, garden hose nozzles

Delrin as a Strong Alternative to Other Plastics

Plastic injection molding is a viable substitute for metal in very demanding applications. If you’re considering a transition from metal to plastic components for your parts and projects, work with an Xcentric expert to understand how a high-performance plastic—like the Delrin plastic— can perform your desired function at an acceptable manufacturing cost in commercially meaningful volumes.

At Xcentric, we will:

If you have a project you need help with, submit your project here, and our team will be happy to provide expert advice.

About Xcentric

Founded in 1996, Xcentric Mold & Engineering is an innovator of on-demand digital manufacturing and continues to lead advances in injection molding and rapid prototyping. We know what it takes to deliver a high-quality product on time and on budget. Xcentric is engineered to be nimble, employs a team of experts in injection molding, and takes an engineer-centric approach to everything we do. Tens of thousands of product developers and engineers across North America trust Xcentric to bring their products to life.

Learn more about what Xcentric can do for you here.

Questions? Contact our friendly sales team here or on 586-598-4636.